Tour Our Services

We provide onshore 2D and 3D seismic data acquisition services in Europe. Check out our services and equipment.

Fit for Purpose

For our clients, whether they are looking for oil & gas traps, mining resources or geothermal faults, we have reached objectives as deep as 5500m and provided high quality images of the subsurface.

Recording Systems

High quality data is obtained by carefully selecting the recording system that best fits a project, and using only the most technologically advanced 2D/3D seismic acquisition systems.

Recording method

Since 2019 we have been using a nodal system as receivers and have developed seismic acquisition expertise with this system on several missions in France, Belgium and Switzerland.

Surveying

Our surveying is DGPS supported. An accurate positioning and surveying is key for the data quality, and for the efficiency of the operations.

Vibroseis Trucks

Our fleet of 9 vibrators, of 48,000 lbs of peak force each, provides the level of energy necessary for deep seismic surveys while remaining very maneuverable even in urban areas, and our experience has proven that they are perfectly suited to missions in Europe.

Our vibrators are controlled with the Sercel vibrator electronics VE464.

Our fleet of industrial vehicles also includes off-road vehicles, truck with trailer, and mechanic service truck.

Drill Rigs

For rough terrains and all areas where access for land vehicles is cost-prohibitive, such as mountain areas, vineyards or orchards, we own a complete set of drill rigs comprising five man-portable rigs, one track carrier rig, and one tractor-mounted drill rig.

Q-HSE

Our Q-HSE management system is based on the guidelines of IAGC (International Association of Geophysical Contractors) and the ISO 14001 standard.

Recording Systems

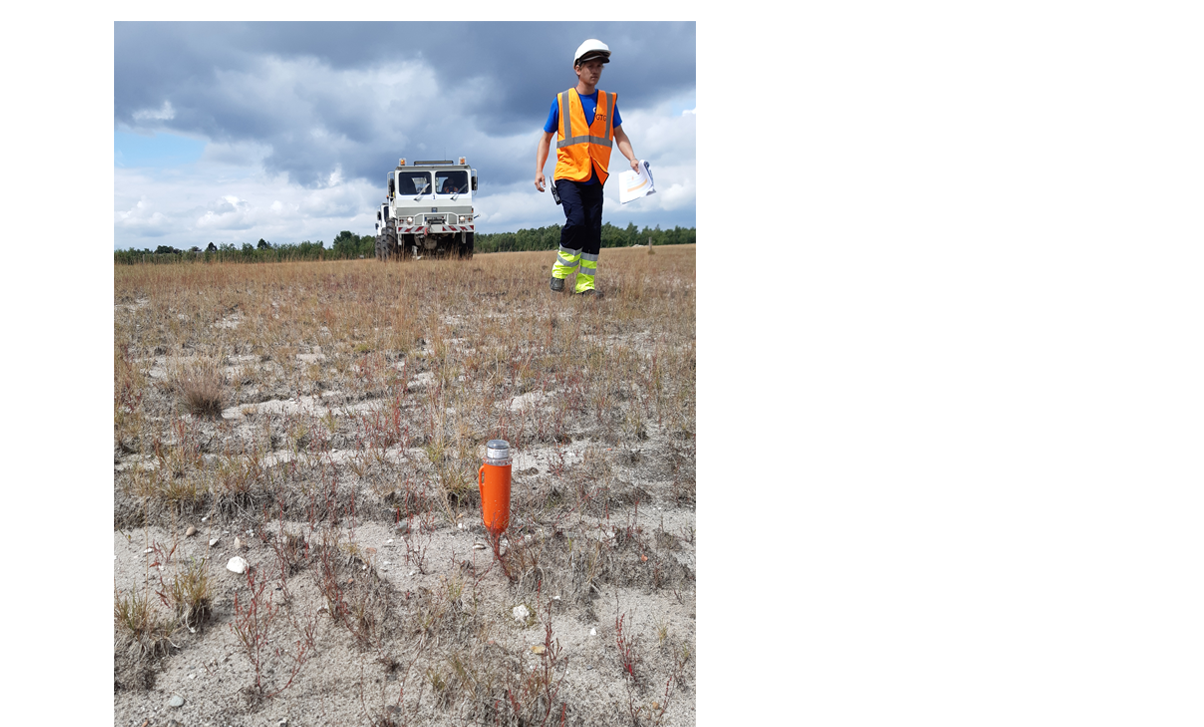

STRYDE Nodal System, the most environmentally-friendly system

Since 2020, we have used the STRYDE nodal system, the smallest and lightest node on the geophysics market today (size 129*41mm, weight 150g).

Stryde node has wireless charging and data harvesting and can record continuously (24h-hour recording) for up to 28 days at -40C. In addition to providing best quality data, outperforming its competitors, the STRYDE system has other numerous operational benefits: 4 to 5 times less vehicles and people required for transportation and deployment/pick-up (can be transported with light vehicles or quads and deployed on foot); No line cutting required for the receivers thereby minimizing the environmental impact; Minimum footprint making it barely visible to the public. All these benefits combined results in a much less crew’s exposure to HSE risks.

STRYDE is a high-quality sensor that is recognized as such by clients who needs to produce images of the subsurface for purposes including geothermal, mining, or oil & gas. This highly performing system provides up to 100,000 active channels with a sampling rate of 1ms or 2 ms.

Recording Method

Tests

With a nodal system there is no need to perform daily tests prior to recording. Stryde nodes have been rigorously tested by the manufacturer and have a track record of delivering outstanding operational efficiency and seismic quality. We have successfully used Stryde nodes during several missions since 2020. Our crew deploys and initializes nodes while ensuring there is good coupling of nodes. Deployment is performed as recommended by Stryde using the deployment and retrieval kit.

Source-Coordination

Overall coordination of recording operations is under the control of our Source-Coordinator at the recording truck via a VHF radio communications network.

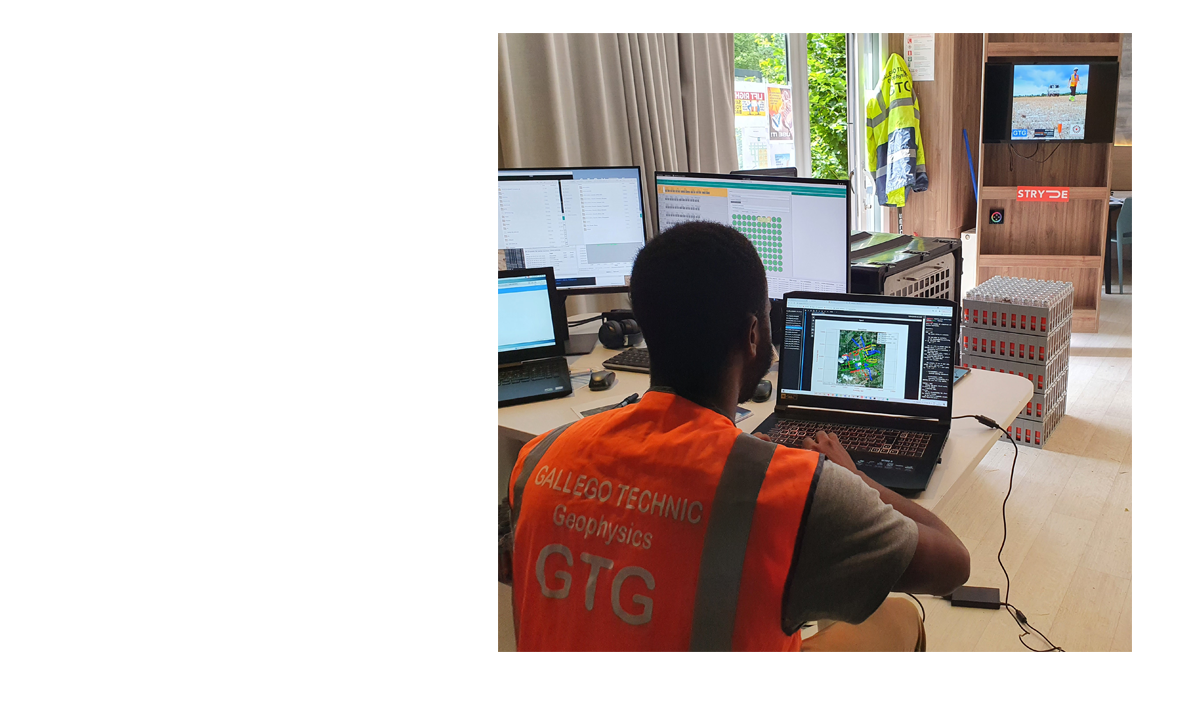

Data Management

Data is recorded continuously by the nodes and harvested once nodes are retrieved and data is downloaded to the server. Data is saved in several backup copies on portable hard disks. Stryde software includes a complete pack of core components for managing data.

Surveying

Market-leading Equipment

Accurate positioning of receiver points and source points is performed with GPS Trimble devices. In forest areas, we use a Trimble S6 Total Station. Occasionally, we use a backpack portable inertial navigation system, the B-PINS X, for areas without coverage such as urban canyons or some forest areas.

Accuracy

Topographic corrections are performed in real time with an accuracy of approximately 10cm.

Vibrators

High energy level for deep objectives

Our fleet includes nine vibrators IVI Mark 4 Y2400 providing each a maximum peak force of 48,000Lbs and a frequency from 5 to 200Hz. Ideal in size and weight for urban areas and narrow tracks: 8m long, 2.45m wide, 3.35m high, 24 tons. Fitted with noise reduction package.

S-Wave Vibrator Mertz 13

Our vibrator was chosen to simulate an earthquake during the LiquefACT research project founded by the EU.

Vibrators Mertz 22

Our fleet also includes five Mertz 22 vibrators, with a peak force of 30,000 lbs.

Drill Rigs

Man-portable Rigs

EMCI Explo 220MPR and Sercel TD150S are both lightweight rigs, designed for difficult-access areas, offering a capacity up to 40m.

Track carrier Rig

Sercel TD150C is a track carrier rig offering a capacity up to 50m.

Tractor-mounted Rig

Ellettari E500T is a drill rig mounted on a wheeled tractor. It has a rotary head with a max. torque of 480Kgm.

Q-HSE

HSE Plan

For each project, we develop a specific HSE Plan that complies with all applicable laws and industry best practices and that addresses the specificities of the project.

Commitments

All our operations are carried out with safety and security in mind, for people, property and the environment. Our Q-HSE management system helps us improve our operational performance and productivity.

Our Golden Rules

Security is our top priority, HSE awareness at all levels, Qualification and training of personnel, Audits and follow-ups, Emergency response plans, Communication.

For more purposes…

High-resolution seismic data acquisition

High-resolution seismic data acquisition We use weight drop, accelerated weight drop or hammer as seismic sources, and deploy STRYDE nodal system receivers.

Rivers and lakes

For seismic operations in rivers and lakes, we use boats to deploy line of receivers, and we use airguns as seismic sources.

Passive Data

We have the capacity to deploy 3C receivers to record passive data.

VSP

We can provide a vibrator as seismic source for VSP operations.